Corrosion involves the reaction between a ferrous metal or alloy and its environment. It is an irreversible interfacial process, which causes the gradual or sometimes accelerated deterioration of a piping system due to the interaction between a ferrous metal, water (or moisture), and oxygen.

Water + Oxygen + Metal = Corrosion

Corrosion can obstruct the flow of water through the sprinkler heads:

• Making the system ineffective

• Increasing the risk of injuries in a fire

• Increasing property damage in a fire

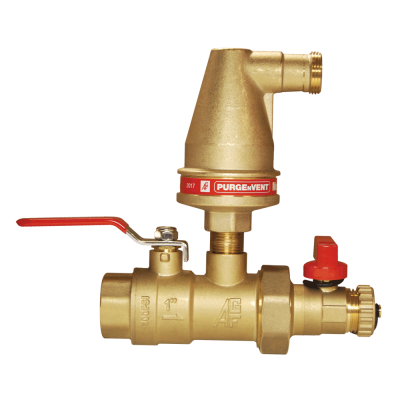

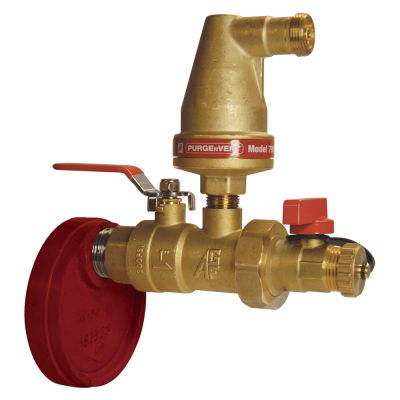

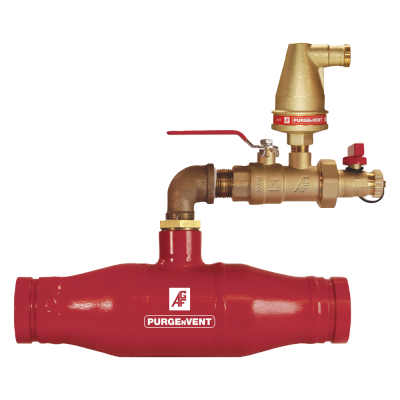

NFPA 13 recommended air vents to eliminate trapped air and prevent corrosion in 2010, and they became a requirement in the 2016 version. If your jurisdiction is on NFPA 13, 2016 edition (or later) you are required to have an air vent on each wet pipe sprinkler system that uses metallic pipe. AGF’s PURGEnVENT manual and automatic air vents make it simple to meet code and reduce the risk of corrosion in your sprinkler system. PURGEnVENT is UL Listed, FM Approved, and the most compact option.

Model 7900 Automatic Air Vent

Model 7930 Endcap Automatic Air Vent

Model 7950 Inline Automatic Air Vent

Model 7910 Manual Air Vent

The 2010 edition of NFPA states that water supplies and environmental conditions be evaluated for conditions that contribute to corrosion. Installing corrosion monitors at established intervals allows building owners and facility managers to understand if there is an internal corrosion issue before leaks are apparent. AGF's CORRinSITE corrosion monitors are a simple and economical way to monitor the progress of corrosion. They require no power or coupons and come in two installation options. They include a plug that sits flush with the side of the pipe and has a hollow center. When the plug corrodes through, moisture enters the chamber and turns a white sight glass fluorescent orange, indicating a certain threshold of corrosion.

Model 7800 Corrosion Monitor

Model 7700 Inline Corrosion Monitor

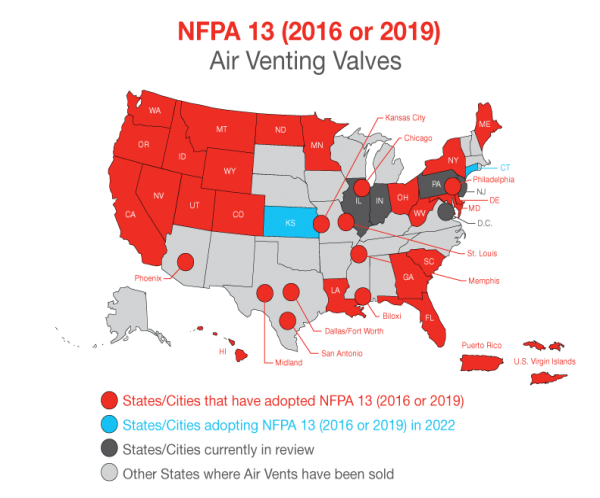

Jurisdictions across the country are adopting NFPA 13 (2016) by itself or by reference through IBC 2018 adoptions. The following chart is a reference of which states have adopted or will be adopting the code to require air vents. *Please consult your AHJ to confirm local code requirements.

For questions about how PURGEnVENT or CORRinSITE can help your corrosion management, contact us to speak to a member of our technical staff.